In one of my recent tasks, I was required to automatically create the product variants for a product master as per all the suggested product variants by the system based on generic product model. So I need to automate the below shown process which if done manually for all items will consume lot of time:

These variant suggestions are based on the defined product variants ( refer to my previous post to get technical understanding of tables storing this information here).

So I did some technical analysis and found the following:

- The class used by standard AX to create variant suggestion is EcoResProductVariantCreationMgr.

- It populates a temperory table to store all the variant suggestions, but by default is keeps the selected field as false.

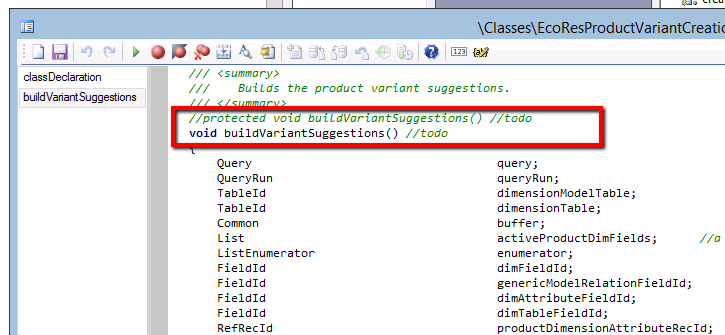

- The function filling this temperoary table is a buildVariantSuggestion() is a protected function, so I cannot call it directly from my code.

So there were few challenges in directly using this class from my job but with few simple customizations in this class, I was able to utilize this class for creating the product variants in a much simple way rather then re writing all the logic inside the class in my job. So I did the following changes:

1. Added a new boolean variable in class declartion and created a parm method for it. This is to initialize this variable when it is called from my custom code and tweak the way temperory table is created:

2. Changed to access modifier of the buildVariantSuggestion()

3. In case the class is called from custom code then we need to mark the records as selected:

So with the above three modifications in standard AX class, I was ready to use this class in my job and I created the below sampe piece of job:

We assigned the EcoResProductMaster record in the args and used that to initialize the class, used the RecId of the productMaster to find the record.

Then we called the parmCalledFromJob method and set it as true to tell system that this class is trigerred from my custom code.

We called the buildVariantSuggestions() , as this is no longer protected I can directly call from my job [This design can be improved by creating a child class instead of changing the access modifier].

So now I ran the job for the same product which I have shown in the first screenshot:

and then when we look at product variants, we see that system has created the product variants :)

P.S --> Before modifying EcoResProductVariantCreationMgr class, please check if this is not conflicting with any other modifications in your system. Especially modifiyng the access modifier is not a recommened thing to do always, however I did this as it was a one time job which we need to run and then reverted back the changes.

Sometimes it is much easy to tweak the standard AX objects and leverage the existing code instead of rewriting the whole logic.

Till my next post.....take care friends and keep sharing.